As an optical designer, often encountered in the work on the photoelectric parameters of the calculation, the previous 100lm / W lamp is a good product, but with the LED development, the requirements have gone up, and now many projects in order to save energy, light from 120 rose to 150, or even 180lm / W, people are very headaches.

The following combination of examples, talk about how to design a photoelectric meet the requirements of the lamps.

The nominal value generally refers to the test data after the product is stable.

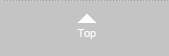

You must first know the standard lamp test, most of the lamps can be completed directly through the integrating ball photoelectric test, according to IESLM79 provides the method to be stable after the light test, as some of the parameter virtual product can be ignored.

Figure 1.IES LM79 requirements for the stability of the lamp

Why the data must be stable, most of the LED products have a decay from the transient to steady-state, and these decay is large, can not be ignored.

By testing these decay sizes, you can wait for a relative thermal attenuation coefficient, see the Redhead section.

Table 2 8-9W bulb on the market test parameters

LED lamp beads selection and testing

Design time, the first is the LED selection, LED book a lot of pages, so you dazzled. Mainly rated power, luminous flux, voltage, color temperature, color rendering index, color tolerance and so on. If you continue further research, there are pta pct, pct, emc several kinds of chip size, there are many kinds of phosphor, phosphor, silicone, gold wire, metal stent has a great trick, these have a great impact on the life of the light source.

For LED, the most important thing is the luminous flux at rated current, for example, the most commonly used 2835 particles, rated 60mA luminous flux 24-26lm. That is not that I will 100pcs the LED soldered in the light bar, 60mA test flux is 240-260lm?

The answer is no, the following is some source of error, the final test report must be based on their own instrument test, so you need to figure out these coefficients.

Table 3 some error summary

However, these coefficients are sometimes inferred to be too much trouble, and ultimately, a lot of one-on-one test. So my idea is that the manufacturers of standard LED lamp beads welded directly to the light board, with a large integral ball test, DC power supply, test the current under multiple data.

If you design a conventional product that does not require light efficiency, the rated current test is fine. But if you need a higher luminous efficiency, those methods do not work, either by choosing brighter beads or by reducing current use, and more often the combination of the two needs to be used.

Table 4 Particle test data

LED lamp beads count

After doing some of the above work, you still lack two important parameters, one is the lamp power conversion efficiency, the other is the optical efficiency of the lamp can be calculated by the following formula, sometimes the face of new lamps can not start, according to Experience some estimates.

Power Efficiency = LED Voltage × Current through LEDs ÷ Input Power

Optical efficiency = lamp luminous flux ÷ bare light source test luminous flux

Note. All of the above are transient tests

Here's how to start a formal calculation:

1, determine the design efficiency

Suppose the customer requirements is 13W1800lm, then the luminous efficiency requirement is 139lm / W

2, determine the use of particle current:

The main impact of light efficiency light transmittance, lamp beads, thermal attenuation coefficient (luminous flux attenuation, VF attenuation), the formula is as follows:

LED lamp pearl effect × transmittance × attenuation coefficient × power efficiency = lighting efficiency

For example, now need to do the lamp, the light transmittance of 94%, transients to steady-state light attenuation of 1.5%, 90% power efficiency, lamp pearl effect that is 139lm / W ÷ 0.94 ÷ 0.985 ÷ 0.9 = 167lm / W. By looking up the table, get a suitable current of 55mA

3, determine the number of lamp beads

Single lamp beads power × number = lamp power × power efficiency × attenuation coefficient

After determining the current, look-up table can get a single power of 0.153W. The number = 13 × 0.9 × 0.975 ÷ 0.153 = 75, but this number can not be used directly, because the power parameters should also be considered, with the appropriate series and parallel, get the final accurate value:

Note. It is possible to calculate the small number of particles required, but the particles used will be obvious, so this design is unreasonable.

Advanced articles - Computing Tools Design

Through the above process, you can calculate a variety of LED lamp beads program. But sometimes often need to calculate the different lamp beads from different vendors, so which program is better, repeat the calculation is a very troublesome thing, so to excel will be much easier.

First of all, the original data, can be obtained as follows two curves, if less demanding, you can use a linear fit, that is, y = ax + b. To be more precise, I use the binomial fit here, y = ax2 + bx + c.

Figure 5 current and forward voltage, light effect

Through the current, all the parameters of lighting will be linked through the form design, it can be more simple calculation of light efficiency. Follow-up can also increase some brightness BIN, voltage BIN, constant current power supply and other parameters, the parameters of the entire batch of product range.

Table 6 Calculate tables and light database

Conclusion: high-efficiency LED is the future trend

LED in use, the electricity into light ratio of about 40%, while other energy used for heating, there is still much room to increase this value, in theory, the luminous efficacy of LED is more than 300. With the gradual improvement of light efficiency, LED will be more and more energy saving, heat will be greatly reduced, and even do not need a separate radiator.

In the design of high light efficiency products, performance and cost have always been very contradictory. Only the various parts can be integrated so as to achieve a balance. The following personal experiences can be used for reference. For any deficiencies, please indicate:

1, the use of a better light source, and reduce the use of light current, to some extent is to achieve the goal, but the cost will be doubled

2, to improve optical efficiency, such as PCB using high reflection white oil, metal reflector surface treatment to reduce PC haze, the use of better diffusion particles, through these optimization, bulb and lamp optical efficiency can reach 97%

3, optimize the power efficiency, the efficiency of non-isolated are now generally 90%, through a certain point of optimization, but also be able to improve 2%

4, to create a better cooling conditions, from the beginning of the article to know, lamps from the transient to steady-state process, the luminous flux will be a lot of instantaneous, if you increase the cooling structure, the use of aluminum plate and increase copper area, will undoubtedly be able to enhance Steady state luminous flux.Source: LED net

Related News

- LED High Bay Light Brief Introduction

- Vietnam LED lighting market has become the emerging focus?

- LED Outdoor Lighting

- Hong Kong-Zhuhai-Macao Bridge

- LED lamp bead welding process dead lamp reason

- Why there is no street light on the highway? - Dec 29, 2017 -

- LED packaging process, how to do a good job of anti-sulfur measures

- High-power LED lamp beads characteristics and technical parameters

- RGB LED three white LED forming principle

- Improve the light extraction efficiency of thermal resistance power LED pack

- LED packaging Collection: I do not know the LED packaging process knowledge

- LED driver power potting use

- LED flip chip technology and process analysis

- Experimental Study on Improving the Temperature Resistance of LED Light Source

- LED Floodlight structure

- Advantages of Driverless Floodlights

- LED flood light installation instructions

- Advantages Of LED Floodlight

- LED flood light applications

- LED six technology to lead the future

Jackson

Jackson

sales01@newlamp-lighting.com

sales01@newlamp-lighting.com