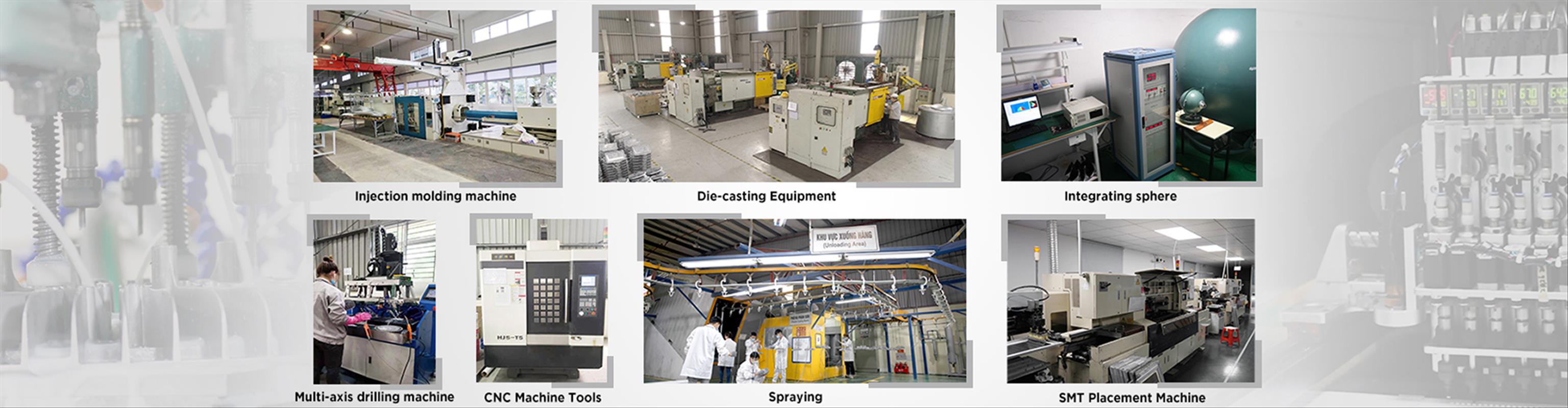

1. Use AC 120V (100~140V) / 220V (200~265V) power supply, bid farewell to expensive LED driver, much cheaper

2. No need to install LED power supply separately, improve production efficiency and save labor cost

3. You can import AC-powered led lights in SKD / CDK to save a lot of work.

4. All components are integrated on the PCB board (DOB solution), automatically assembled by SMT machine, reducing the defect rate

5. Reduced transportation and storage costs due to driverlessness, saving weight and volume

6. Maintenance is simple and convenient, no need to struggle between LEDs or drivers, just replace the entire PCB board.

7. Modular design, simple structure, flexible combination, easy to make customized solutions

8. ACLED modules can be used separately or illuminated in SKD / CKD for internal assembly to save responsibilities or prepare lights

Related News

- Why use plant growth lights

- After-sales service for ufo high bay light

- Advantages and disadvantages of ultraviolet sterilization

- Another materials have New breakthrough-Graphene is the protagonist

- will be implemented from April 1

- LED flood light is broken, what should I do?

- UFO high bay lights

- How far and how large a high-power LED floodlight can illuminate

- LED flood light is broken, what should I do?

- Our Factory(Newlamp Lighting)Testing Standards for order UFO high bay lights.

- Module LED Tunnel Flood Light

- Shenzhen Newlamp New Product Launch Linear high bay .similar like Linear light hence the name Features

- The LED Tunnel light used outdoors is very similar to the LED floodlight

- OLED application

- Meet LED lighting needs in multiple markets with a single solution

- Led sensor light is a new type of intelligent lighting products.

- How to Learn about outdoor lighting design,starting with Floodlighting

- 360W LED Linear High Bay Light (Driverless)

- How to working the Microwave Motion Sensor LED UFO High Bay Lights

- How do Driverless LEDs work?

Jackson

Jackson

sales01@newlamp-lighting.com

sales01@newlamp-lighting.com